Elegance 20

Introducing our Elegance 20 flush-fronted cubicle system, meticulously crafted from 19-20mm moisture-resistant MDF board and faced with High-Pressure Laminate (HPL). This premium system features hardwood-edged rebated doors and pilasters, ensuring both durability and a seamless, sleek finish. The Elegance 20 cubicle is designed specifically for dry environments, combining aesthetic appeal with robust construction, making it the ideal choice for high-end commercial spaces. With its flush-fronted design, it offers a modern and sophisticated look that enhances any interior while delivering long-lasting performance.

Applications

The Elegance 20 Cubicle washroom system is designed to provide a versatile and durable solution for various washroom environments, particularly those that require a high level of hygiene and efficiency. The Elegance 20 system is ideally suited for applications in dry environments, such as office buildings, schools, healthcare facilities, and retail spaces, where maintaining cleanliness and a professional appearance is critical. Its robust design and easy maintenance make it an excellent choice for areas with high foot fall.

Features

The Elegance 20 cubicle has many features including the following:

- Durable product suitable for dry environments

- Bolt through fixings & secretly fixed options available

- Hardwood edges to both pilasters and doors

- 2mm PVC lipped edges to partitions

- DDA Compliant turn lock with emergency release facility

- Pedestal legs adjustable to accommodate uneven floors

- Can be manufactured to suit various height requirements

- Manufactured only in High Pressure Laminate

- Available in over 100+ laminate colours

Materials

High-Pressure Laminate (HPL) is a durable, decorative surface material made by bonding multiple layers of paper under high heat and pressure. It is widely used in various applications, particularly in furniture, countertops, wall panels, and washroom cubicles due to its resilience and aesthetic versatility.

Composition of High-Pressure Laminate (HPL):

- Overlay (Top) Layer: This is a clear, protective layer that provides resistance to scratches, stains, and general wear. It’s usually made from melamine resin, which hardens into a tough, transparent surface.

- Decorative Layer: Below the overlay, this layer contains the printed design or colour, which gives the HPL its appearance. It can mimic a variety of materials, such as wood, stone, or solid colours.

- Core Layers: These consist of several layers of kraft paper impregnated with phenolic resin. The number of layers can vary depending on the desired thickness and strength of the final product. The phenolic resin gives the core its rigidity and strength.

Manufacturing Process:

- Impregnation: Kraft paper (for the core) is impregnated with phenolic resin, while the decorative paper is impregnated with melamine resin. These resins are thermosetting, meaning they harden when exposed to heat.

- Stacking: The impregnated papers are stacked, with the decorative paper and overlay on top of the kraft paper layers.

- Pressing: The stack is placed in a high-pressure press, where it is subjected to heat (typically around 120-150°C) and pressure (about 1,000 to 1,400 PSI) for a set amount of time. This process fuses the layers together into a single, solid laminate sheet.

- Cooling and Finishing: After pressing, the laminate is cooled and then trimmed to size. The surface can also be finished with textures or gloss levels, depending on the intended use.

Characteristics of HPL:

- Durability: HPL is resistant to impact, scratches, moisture, and heat, making it ideal for high-traffic and demanding environments.

- Versatility: It comes in a wide range of colours, patterns, and finishes, including wood grains, metallics, and solid colours.

- Maintenance: It is easy to clean and maintain, as the non-porous surface resists stains and bacteria.

- Cost-Effectiveness: HPL provides an affordable alternative to natural materials, offering a similar appearance with enhanced performance.

Because of these properties, High-Pressure Laminate is a popular choice in various industries, especially in applications where both durability and aesthetics are important.

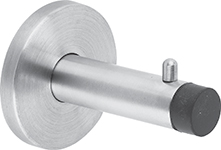

Fixtures and fittings

Elegance 20 Cubicle uses durable stainless-steel hardware, which provides long-lasting strength and resilience. Stainless steel is an ideal choice for environments where durability and resistance to corrosion are crucial, such as in high-traffic or high-moisture areas. The material’s strength ensures that the cubicle can withstand daily wear and tear, while its resistance to rust and other forms of corrosion make it easy to maintain and clean. This hardware choice also contributes to a sleek, modern aesthetic, enhancing the overall appearance and functionality of the cubicle.

Dimensions

- Standard Height – 2100mm with 150mm floor clearance

- Floor to ceiling cubicles possible with 20mm foot or set in floor channel

Colours

Elegance 20 cubicle is only manufactured in High Pressure Laminate and Total Laminate Systems prides itself on only using the finest of materials. Please see below our standard colour offering. Alternate suppliers can be used, please note rates may vary.

Polyrey Washroom Collection PDF

Extras

Please see additional information to assist with specifying Total Laminate Systems Elegance 20 cubicle.

Accreditations / Certifications

All of our site operatives are CSCS registered and are undergoing continuous health and safety training. Below are the list of professional accreditations / certifications we are also compliant with. Please click on each logo for further accreditation / certification information: